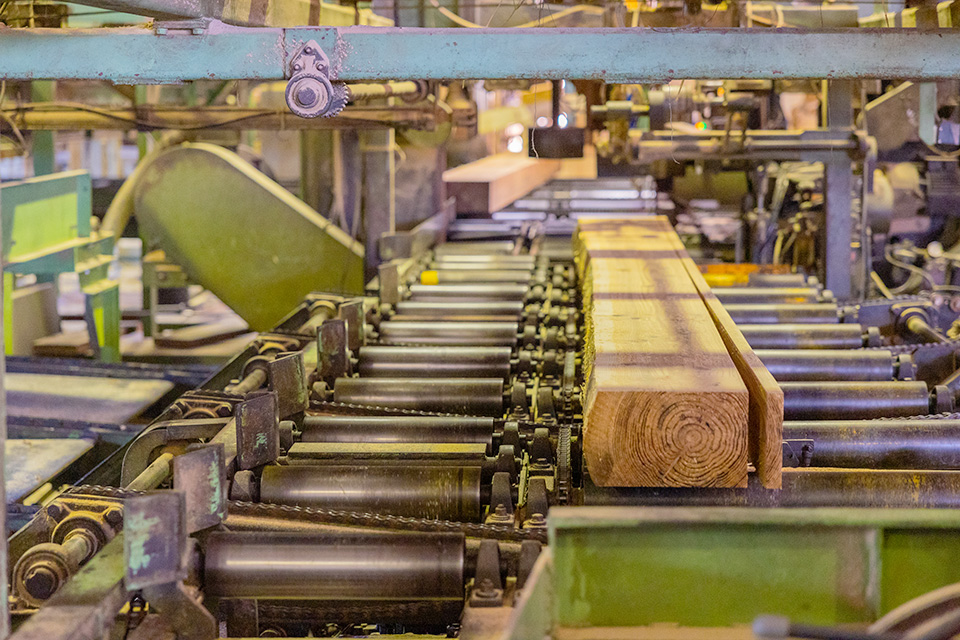

Most Obisugi timbers are cut at 4-meter intervals (primary process) to be processed for building materials at the lumber mill.

After the timber is sawn, in the secondary processing the timbers undergo drying, planer finishing, and then processing into wall and floor materials to complete the product.

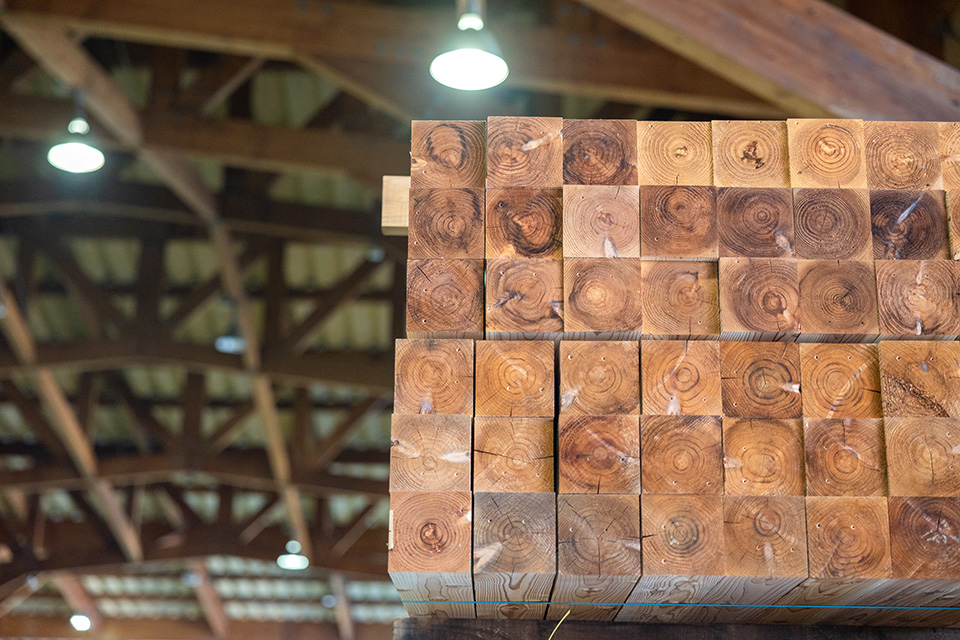

Drying

Dryer

The moisture content in the timbers is reduced from 60-70% raw wood to 25-13% seasoned wood.

The moisture content in the timbers is reduced from 60-70% raw wood to 25-13% seasoned wood.

*The size of the dryer in the photo is 50㎥. It takes about 8 days to dry a standard-size square piece of wood, though the drying time varies depending on thickness.

Planer Finish

Molder

fter drying wood, four sides of the product are planed to smooth the surface.

*Our machine allows for planing of all four sides at the same time.

Wall Paneling and Flooring

We process into squared timbers, scaffolding planks, scantling, boards, and others besides.

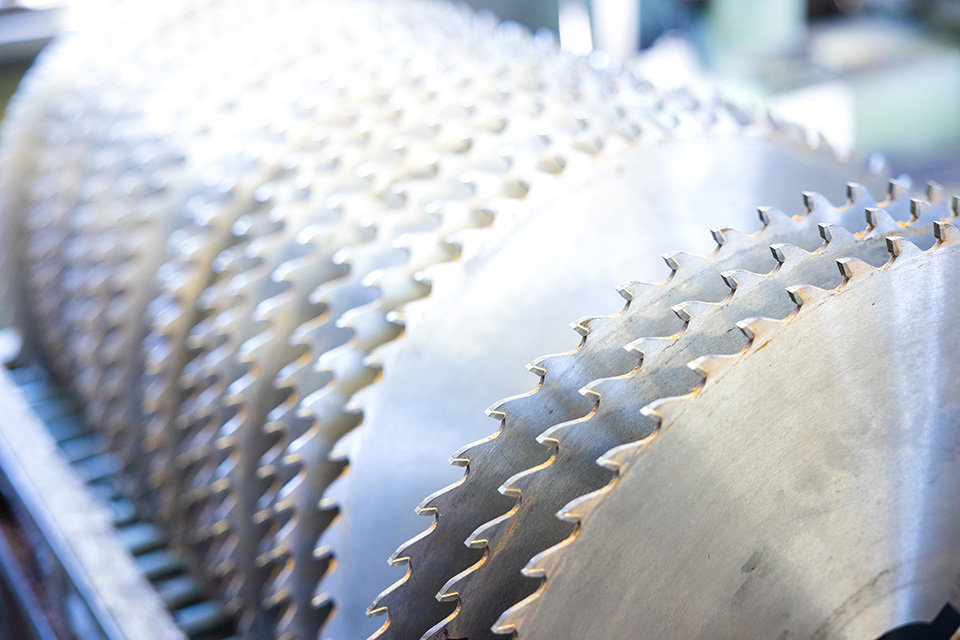

Saw Sharpening Factory

Band saws and circular saws are polished.

We also contribute to the local forestry industry by providing technical guidance and research.